Proprietary Ingredient Process

Following the discovery of the functional benefits of our patented substance, Ceriporia lacerata, for food and pharmaceutical use.

Fugenbio developed an optimized fermentation process and established advanced extraction technology to maximize its active compounds.

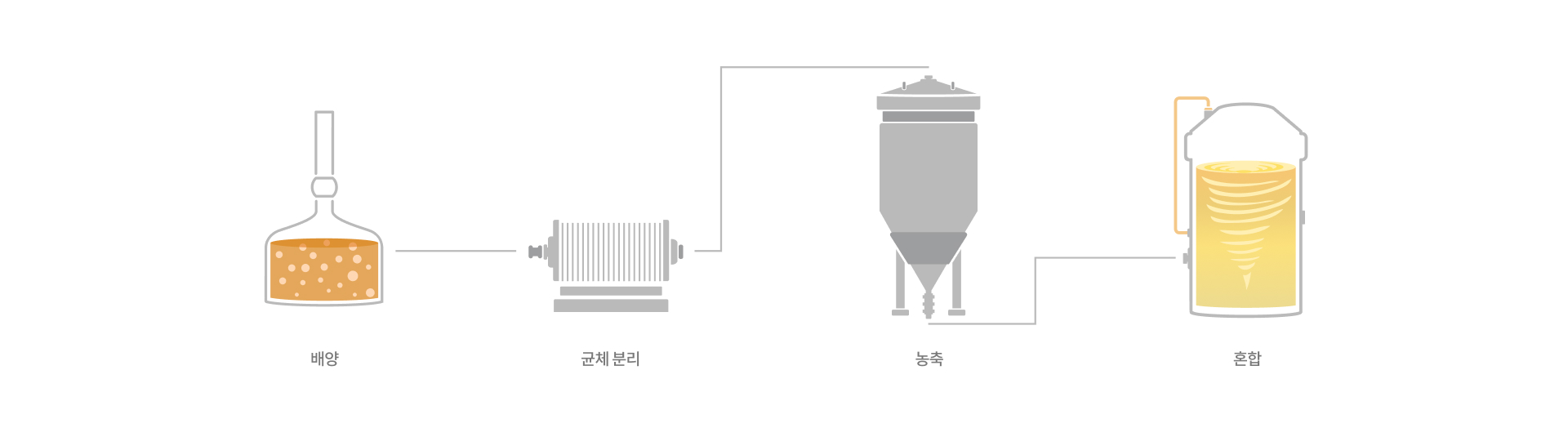

Production Process

To produce our patented ingredient, we first perform a pre-cultivation step to prepare optimal conditions for microbial growth.

Once the microorganisms reach a uniform state, large-scale liquid fermentation is carried out.

After cultivation, the broth and mycelium are separated.

The concentrated extract is then recombined with the mycelium to enhance the efficacy of the final material.

| Cultivation | Large-scale fermentation of verified microbial strain |

| Separation | Isolation of broth and mycelial biomass |

| Concentration | Concentration of the separated extract |

| Recombination | Blending the concentrated extract with the mycelium |

Strain Management

& Safety Assurance

To ensure the identity of the mother strain (master culture), DNA sequencing was performed, confirming over 99% genetic similarity.

The strain is securely deposited with a professional institution and managed through a three-stage safety system,

ensuring stability and long-term preservation of this valuable microbial resource.